![]() info@aarviengineering.com

info@aarviengineering.com ![]() +91 96622 06454

+91 96622 06454

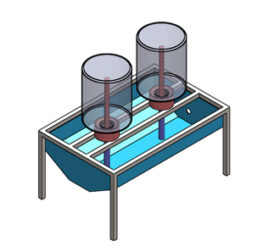

Cup Filling And Sealing Machine

Cup or Glass Filling and Conduction Machine – Cup filler – Cup Filling and Sealing Machine – Cup filling machine

Filling Range: 5 gm to 1 Kg (with the help of Change Parts)

Output: 10 to 60 bottles per minute. (Depending upon Ointment Characteristics and Filling Size)

Applicable Industry:

Juice, Dairy Products, Food, Chemical and relevant

Suitable for Different Types of Material like water, juice, shrikhand, yogurt, curd, dahi, butter milk, fruit pulp, ice-cream, lassi, Chemical, Adhesives and Relevant

The Automatic Paste filling and conduction is compact and highly efficient machine with elegant look. This multi function multi featured machine meets the custom requirements of filling of liquid material in Pet and HDPE bottles.

Features

The Cup Filling and Sealing Machines are designed for the purpose of filling and sealing cups. It has Auto Cup Feeding System. These machines can quickly and automatically fill cups with the product. It seals the cup after it fills it with the product. This machine is most suitable for filling and sealing juices, Lassi, Flavored Milk, Butter, Water Glass, Yogurt, Adhesive, chemicals, Grout and more. It is a Cup or Glass Filling Machine that is easy to use, has a low maintenance cost and helps in reducing wastage of product. This Cup filler is suitable for filling and sealing the products such as syrups, suspensions and various viscous liquids. The Cup filling machine helps in saving time, effort, and energy while making sure that each cup is filled properly with the desired product.

Operation: Empty cups or glass or containers are being fed manually or by stacker into the cavity. The next Operation is filling through Syringes. Then container comes under conduction unit where Aluminium Foil or Laminate Roll get cut through a cutting die and conduction done by heating.

Technical Details

| Number Of Filling Head | 1 |

| Number of Inner Head | NA |

| Number of Sealing Head | NA |

| Number of Applicator | NA |

| Production / Rate | 30 To 35 Tubes /Min (Depend On Fill Size And Material Characteristics and Efficiency of Operator) |

| Fill Size | 5 ml to 1000 ml (with the help of change parts) |

| Type of Product | Plastic, Leminated, Aluminium Tubes |

| Type of Filling Material | Cream, Paste, Semi Solid |

| Type of Seal | NA |

| Type of Label | NA |

| Label Specification | NA |

| Material Contact Part | SS3 316 |

| Material Non-Contact Part | SS 304, SS Cladded MS Body Plate |

| Type of Technology | Syringe based, Pneumatic/ Mechanical System, Controller Based |

Do you have any question?

Feel free to contact us anytime.