![]() info@aarviengineering.com

info@aarviengineering.com ![]() +91 96622 06454

+91 96622 06454

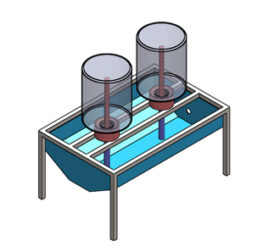

Semi Automatic Capping Machine

Suitable for ROPP Capping, Screw Capping, CRPP Capping, Crown Capping, Dosing Cup Sealing

Suitable for sealing all types of Bottles and Containers and Jars for Pharmaceuticals, Ayurvedic, Nutraceutical, Dairy, Juice, Chemical, Food, Edible Oil Lubricant Oil, Cosmetics, Pesticides and Agro Industries.

Output per min: 12 to 18 Sealing per min (Depend on feeding capacity of user)

A Semi Automatic Capping Machine is used to apply caps over the ends of bottles. This type of capping machine is easy to use and consume less space. The Capping Machine offered here is suitable for ROPP Capping, Screw Capping, CRPP Capping, Crown Capping and Dosing Cup Sealing. The machine is capable of capping all types of bottles and containers. This machine can be synchronized with other machines like Filling, Visual Inspection, and Induction Sealing Machine. This is a semi automatic machine which means it works in manual mode with human assistance. Semi-automatic machines are preferred by many industries where the output is small. The machine is widely used for capping bottles of containers filled with Pharmaceuticals, Juice, chemicals, Food, Cosmetics and more. The machine can cap 15 To 25 Bottles per minute and consumes less power. If you are looking for a semi automatic ropp capping machine or capping machine for bottles, the Aarvi Engineering Semi Automatic Capping Machine is the best match for your need.

Features

Technical Details

| Number Of Filling Head | NA |

| Number of Inner Head | NA |

| Number of Sealing Head | 1 / 4 / 6 / 8 |

| Number of Applicator | NA |

| Production / Rate | 15 To 25 Bottle /Min (Depend On Bottle Shape, Cap Size, Cap Type, Operator Efficiency) |

| Fill Size | NA |

| Type of Product | Plastic, Glass, HDPE bottles, tins and containers |

| Type of Filling Material | NA |

| Type of Seal | Plastic, Aluminium, Rubber Stopper, Inner Plug, Dosing Cup, Crown, Lug, CRPP, Seal, Lid |

| Type of Label | NA |

| Label Specification | NA |

| Material Contact Part | SS3 316 |

| Material Non-Contact Part | SS 304, SS Cladded MS Body Plate |

| Type of Technology | Controller Based |

Do you have any question?

Feel free to contact us anytime.