![]() info@aarviengineering.com

info@aarviengineering.com ![]() +91 96622 06454

+91 96622 06454

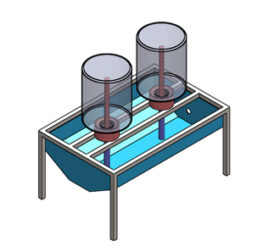

Automatic Servo Base Filling Machine

PLC Based Fully Automatic Liquid Filling Machine – BULK FILLING – Viscous Filling Machine

Filling Range: 50 ml to 5 Ltr / 250 ml to 15 Ltr / 500ml to 25 Ltr (No Need of Change Parts)

Output: 20 to 24 bottles per minute for 1 Liter. (Depending upon Liquid and Bottle)

Applicable Industry:

Lubricant Oil, Edible Oil, Ghee, Chemical, Cleaning Material, Agrochemical, Pesticides, Food and Beverages, Dairy, Juice, Pharmaceutical, Ayurvedic, Nutraceutical, Cosmetic and relevant

Suitable for Different Types of Material like Milk, Syrup, Juice, Honey, Sauce, Cleaning Products, Phenyl, Shampoo, Handwash, Glycerin, Solvent, Chemical, Lotion and relevant.

Features

The Automatic Servo Base liquid filling machine is compact and highly efficient machine with elegant look. This multi function multi featured machine meets the custom requirements of filling liquid and viscous material in glass, plastic and aluminum bottles.

Operation: The machine has its own pumping system to connect the machine with main tank. The flow of liquid is measured and converted in to electronic signals being controlled by PLC based circuitry. Minimum adjustment required to set different capacities from 50 ML to 5 liters with varying containers. The entire range can be set on the same machine without any change parts. PLC controlled latest technology with variable recipe data.

The filling pump synchronized with conveyor drive and conveyor drive controlled by AC frequency drive. The speed can be set in terms of bottles per minute. The conveyor drive consists of a hollow shaft, geared motor controlled by AC frequency drive. A knob can set the speed of conveyor.

Technical Details

| Number Of Filling Head | 2/4/6/8 |

| Number of Inner Head | NA |

| Number of Sealing Head | NA |

| Number of Applicator | NA |

| Production / Rate | 20 To 30/30 To 40/40 To 50/50 To 60 Bottle /Min (Depend On Fill Size And Material Characteristic |

| Fill Size | 5 ml to 2.5 Ltr / 50 ml to 5 Ltr /100 ml to 10 Ltr/ 500 ml to 25 Ltr (Wthout help of change parts) |

| Type of Product | Plastic, Glass, HDPE bottles, tins and containers |

| Type of Filling Material | Liquid Low Density, High Density, Viscous, Hot, Cold |

| Type of Seal | NA |

| Type of Label | NA |

| Label Specification | NA |

| Material Contact Part | SS3 316 |

| Material Non-Contact Part | SS 304, SS Cladded Ms Body Plate |

| Type of Technology | Linear, Pump Based, Fully Automized with PLC HMI Touch Screen |

Do you have any question?

Feel free to contact us anytime.