![]() info@aarviengineering.com

info@aarviengineering.com ![]() +91 96622 06454

+91 96622 06454

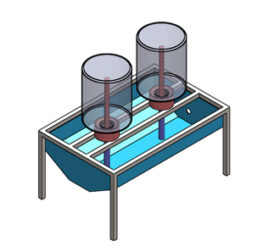

Automatic Auger Powder Filling Machine

Filling Range: 10 gm to 1 Kg (with the help of Change Parts)

Output: 20 to 60 bottles per minute. (Depending upon Powder Characteristics and Filling Size)

Applicable Industry:

Pharmaceutical, Ayurvedic, Nutraceutical, Cosmetic, Food, Agrochemical and relevant

Suitable for Different Types of Material like Pharmaceutical Dry Powder Syrup, Protein Powder, Ayurvedic Powder, Granulesm Food Products and relevant

The automatic powder and granules filling machine is compact and highly efficient machine with elegant look. This multi function multi featured machine meets the custom requirements of filling powder and granules material in glass, plastic and aluminum containers.

Features

Operation: Automatic Auger Type Powder Filling Machine is a compact model used for filling Powder into bottles or Jar. The incoming dry bottle (sterilized and silicones) is fed through in feed Turn Table with suitably guided on the moving S.S. flat conveyor belt at the required speed for feeding. The filling head is mounted on the machine top plate. When the bottle reaches the filling station, it will be held by the pneumatic bottle holder. Immediately it will be sensed by the bottle sensor as soon as it gets the signals from the sensor magnetic clutch starts to rotate which is mounted on the auger shaft. It will fill the desired amount of powder into the bottle through the auger. After filling of bottle pneumatic piston goes back and releases the bottle to move on the conveyor. The main advantage of this machine is Pneumatic bottle holding system is directly connected with Auger rotation, so till the bottle get filled with powder as per set value, the pneumatic system will not going to release the bottle.

Technical Details

| Number Of Filling Head | 1 / 2 / 4 / 6 |

| Number of Inner Head | NA |

| Number of Sealing Head | NA |

| Number of Applicator | NA |

| Production / Rate | 20 To 40 / 40 To 60 / 60 To 80 / 80 To 100 Bottle /Min (Depend On Fill Size And Material Characteristic) |

| Fill Size | 50 gm to 1000 gm (With the help of change parts) |

| Type of Product | Plastic, Glass, HDPE bottles, tins and containers |

| Type of Filling Material | Dry Powder Syrup, Granules, Food Powders, Cosmetic Powders, Chemical Powders |

| Type of Seal | NA |

| Type of Label | NA |

| Label Specification | NA |

| Material Contact Part | SS3 316 |

| Material Non-Contact Part | SS 304, SS Cladded MS Body Plate |

| Type of Technology | Linear, Controller Based / PLC Based |

Do you have any question?

Feel free to contact us anytime.