![]() info@aarviengineering.com

info@aarviengineering.com ![]() +91 96622 06454

+91 96622 06454

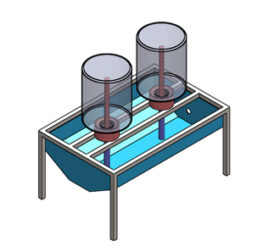

Rotary Tube Filling Machine

Filling Range: 5 gm to 1 Kg (with the help of Change Parts)

Output: 15 to 40 bottles per minute. (Depending upon Ointment Characteristics and Filling Size)

Applicable Industry:

Pharmaceutical, Ayurvedic, Nutraceutical, Cosmetic, Food, Agrochemical and relevant

Suitable for Different Types of Material like Cream, Ointment, Paste and Relevant

Aarvi Engineering’s Rotary Tube Filling Machine is used to fill and seal crimp, batch code and eject the laminated and plastic tubes for various industries like Pharmaceutical, Ayurvedic, Nutraceutical, Cosmetic, Food and Agrochemical. The machine can fill 15 to 40 tubes and has a filling range of 5 gm to 1kg. The machine is suitable for filling different types of material such as Cream, Ointment, Paste, Gel, Tooth Paste and other relevant types of material. The machine is sturdily designed for viscous and paste filling and it fills 30 to 80 tubes per minute. The machine has stainless steel matt finished body and has multiple Filling ranges with arrangements of different change parts. The machine has the most reliable sealing system and works smoothly and is easy to operate.

Features

Technical Details

| Number Of Filling Head | 1 / 2 |

| Number of Inner Head | NA |

| Number of Sealing Head | NA |

| Number of Applicator | NA |

| Production / Rate | 8 To 12 / 16 To 20 Bottle /Min (Depends On Bottle Size, Material characteristics and operator Efficiency) |

| Fill Size | 10 ml to 1 Ltr (With the help of change parts) |

| Type of Product | Plastic, Glass, HDPE bottles, tins and containers, Pouches |

| Type of Filling Material | Paste, Semi Solid, Hot, Cold |

| Type of Seal | NA |

| Type of Label | NA |

| Label Specification | NA |

| Material Contact Part | SS3 316 |

| Material Non-Contact Part | SS 304, SS Cladded MS Body Plate |

| Type of Technology | Pump / Syringe Based, Controller Based / PLC Based |

Do you have any question?

Feel free to contact us anytime.