![]() info@aarviengineering.com

info@aarviengineering.com ![]() +91 96622 06454

+91 96622 06454

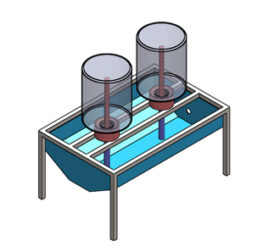

Automatic Capping Machine

Suitable for ROPP Capping, Screw Capping, CRPP Capping, Crown Capping, Dosing Cup Sealing

Suitable for sealing all types of Bottles and Containers and Jars for Pharmaceuticals, Ayurvedic, Nutraceutical, Dairy, Juice, Chemical, Food, Edible Oil Lubricant Oil, Cosmetics, Pesticides and Agro Industries.

Automatic Capping Machine is a system from Aarvi Engineering that is specially designed for ROPP Capping, Screw Capping, CRPP Capping, Crown Capping and Dosing Cup Sealing. This ROPP Capping Machine features a unique hopper to increase the storage capacity of a bowl and has a microcontroller based system with the latest technology. This is the best machine to use for capping bottles of any type and size. This Automatic Multi Head Bottle Capping Machine is perfect for any business that needs to cap their bottles quickly and effectively. It is not only fast but also can save your business money in the long run because it has a built-in, easy-to-use design. It is suitable for Plastic, Aluminium, Rubber Stopper, Inner Plug, Dosing Cup, Crown, Lug, CRPP, Seal, Lid type of seal. The products suitable are Plastic, Glass, HDPE bottles, tins and containers. It is majorly used in Pharmaceuticals, Ayurvedic, Nutraceutical, Dairy, Juice, Chemical, Food, Edible Oil Lubricant Oil, Cosmetics, Pesticides and Agro Industries.

Features

The Automatic electronic liquid filling machine is compact and highly efficient machine with elegant look. This multi function multi featured machine meets the custom requirements of filling liquid and viscous material in glass, plastic and aluminum bottles.

Operation: The machine has its own pumping system to connect the machine with main tank. The flow of liquid is measured and converted in to electronic signals being controlled by PLC based circuitry. Minimum adjustment required to set different capacities from 50 ML to 5 liters with varying containers. The entire range can be set on the same machine without any change parts. PLC controlled latest technology with variable recipe data.

The filling pump synchronized with conveyor drive and conveyor drive controlled by AC frequency drive. The speed can be set in terms of bottles per minute. The conveyor drive consists of a hollow shaft, geared motor controlled by AC frequency drive. A knob can set the speed of conveyor.

Technical Details

| Number Of Filling Head | NA |

| Number of Inner Head | NA |

| Number of Sealing Head | 1 / 4 / 6 / 8 |

| Number of Applicator | NA |

| Production / Rate | 30 to 50 / 60 to 80 / 80 to 100 / 100 to 120 Bottle /Min (Depend On Bottle Shape, Cap Size and Cap Type ) |

| Fill Size | NA |

| Type of Product | Plastic, Leminated, Aluminium Tubes |

| Type of Filling Material | NA |

| Type of Seal | Plastic, Aluminium, Rubber Stopper, Inner Plug, Dosing Cup, Crown, Lug, CRPP, Seal, Lid |

| Type of Label | NA |

| Label Specification | NA |

| Material Contact Part | SS3 316 |

| Material Non-Contact Part | SS 304, SS Cladded MS Body Plate |

| Type of Technology | Linear / Rotary, Controller Based / PLC Based |