![]() info@aarviengineering.com

info@aarviengineering.com ![]() +91 96622 06454

+91 96622 06454

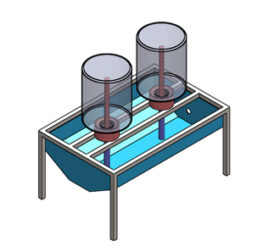

Viscous Filling Machine

PLC Based Semi Automatic Liquid Filling Machine – BULK FILLING – Viscous Filling Machine

Filling Range: 50 ml to 5 Ltr / 250 ml to 15 Ltr / 500 ml to 25 Ltr (No Need of Change Parts)

Output: 16 to 20 bottles per minute for 1 Liter. (Depending upon Liquid and Bottle)

Applicable Industry:

Pharmaceutical, Ayurvedic, Nutraceuticals, Cosmetic Lubricant Oil, Edible Oil, Ghee, Dairy Products, Chemical, Cleaning Material, Agrochemical, Pesticides, Food and Beverages, Dairy, Juice and relevant

Suitable for Different Types of Material like Milk,Syrup,Juice,Honey, Sauce, Cleaning Products, Phenyl, Shampoo, Handwash, Glycerin, Solvent, Chemical, Lotion and relevant.

Features

Viscous Filling Machine is double head compact and highly efficient machine with elegant look. This multi function multi featured machine meets the custom requirements of filling liquid and viscous material in glass, plastic and aluminum bottles.

Operation: Bottles have to place manually below the filling nozzles at tray of machine. The filling range can be set from keypad directly. By giving start command the liquid dispenses from the nozzle. Once the set volume of liquid has been dispensed, the nozzle shuts off immediately in positive way and ensures zero dripping.

Technical Details

| Number Of Filling Head | 2 / 4 / 6 / 8 |

| Number of Inner Head | NA |

| Number of Sealing Head | NA |

| Number of Applicator | NA |

| Production / Rate | 20 To 30 / 30 To 40 / 40 To 50 / 50 To 60 Bottle/Min (Depend On Fill Size And Material Characteristic) |

| Fill Size | 5 ml to 2.5 Ltr / 50 ml to 5 Ltr / 100 ml to 10 Ltr / 500 ml to 25 Ltr (Without help of change parts) |

| Type of Product | Plastic, Glass, HDPE bottles, tins and containers |

| Type of Filling Material | Liquid Low Density, High Density, Viscous, Hot, Cold |

| Type of Seal | NA |

| Type of Label | NA |

| Label Specification | NA |

| Material Contact Part | SS3 316 |

| Material Non-Contact Part | SS 304, SS Cladded MS Body Plate |

| Type of Technology | Linear, Pump Based, Fully Automized with PLC HMI Touch Screen |

Do you have any question?

Feel free to contact us anytime.